Probably took me about four hours ;-D So much checking and measuring.

I’m not an expert, definitely don’t use this as a guide 🙂

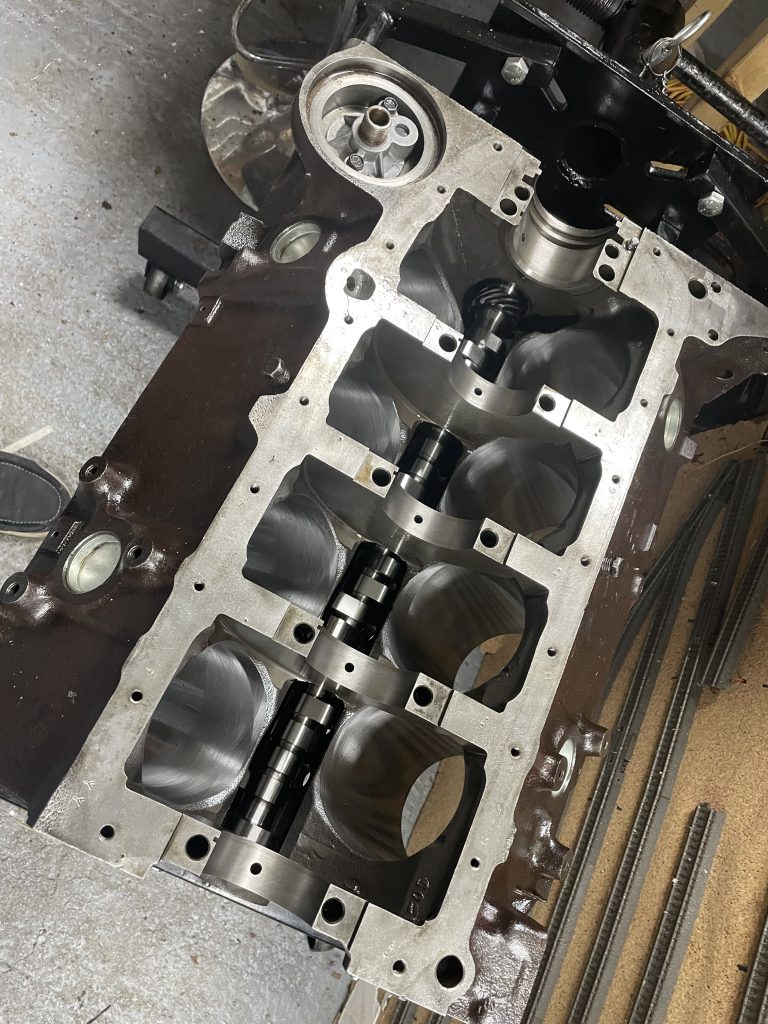

Block with cam fitted.

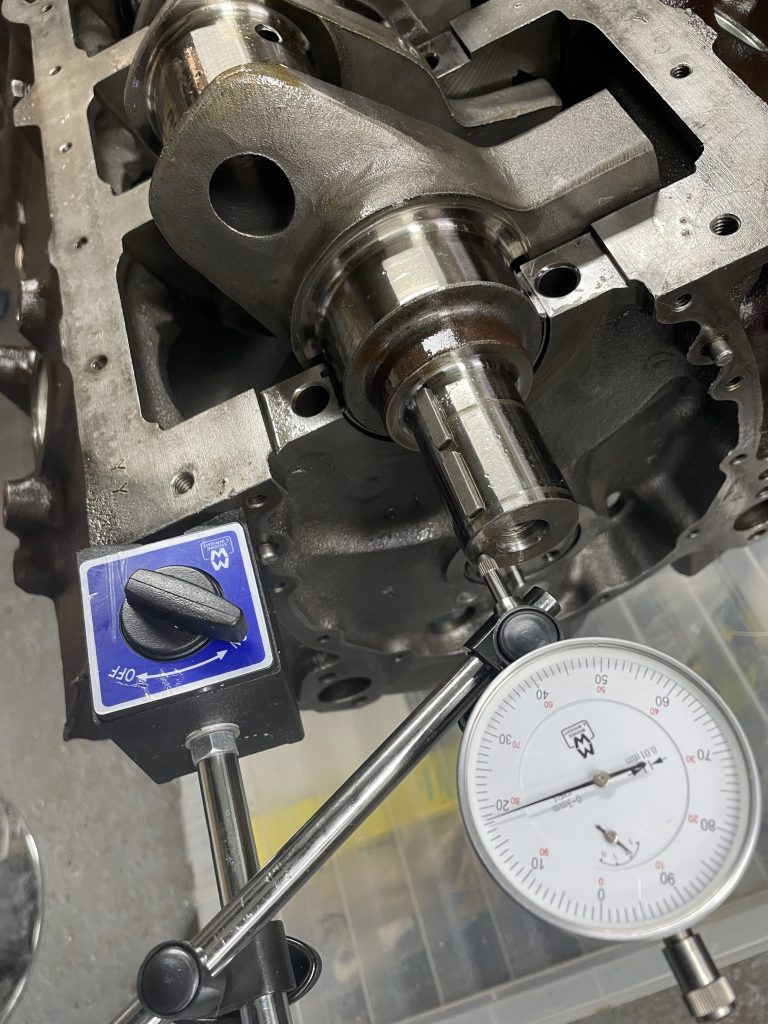

Crank fitted.

Measuring bearing clearance using Plastigage.

Measuring end-float.

Everything I measured up until this point was within spec. The end-float did drop from 0.0055″ to 0.0028″ when I tightened the thrust bearing but I did shove the crank backwards and forwards before tightening and was told this is normal.

Test spin

This company is plain dangerous. After starting to build this engine, I measured the piston to cylinder clearance, which, according to the piston specification sheet (that MJA was handed) should be 0.0035″. The cylinders MJA bored are somewhere between 0.0045-0.0055″, not even consistent.

They also filed the piston rings. Moly rings where the top ring is meant to have a gap of 0.018″ and the second ring 0.020″. Some of them, both top and second, are as low at 0.016″. Thank god I measured them.

MJA is just plain dangerous. How can no-one have picked up on this before?

I might be able to salvage this by having the piston skirts coated but it is even more money MJA has cost me.

I have had the mis-fortune of dropping off an engine block for re-manufacturing at MJA Engineering in Broomgrove and want to warn other against this company as they really don’t know what they’re doing. I think it’s a case of “Don’t attribute to malice what is adequately explained by stupidity”.

I dropped off an SBC block at MJA Engineering to have it re-manufactured and bored over to become an 383 stroker. All seemed fine, they were friendly and appeared knowledgeable, no alarm bells ringing at this point. I picked the block up again, £940 lighter.

Upon inspection in my workshop, I noticed a scratch in one of the bores. It was black and you could feel it with your nail. You could also clearly feel the hone pattern with your fingers. Not being an expert, I posted the photo of the scratch on a forum. And yes, I know people on fora are not necessarily experts either, but feedback and discussion can still be helpful.

Everyone on the forum was in agreement though, and I even started PMing with a machinist about the honing. It was absolutely too rough for modern rings. MJA had used a grit (150) that was only fitting back in the days of steel rings.

I contacted MJA about this and they told me that:

(They later admitted they did not have any stones above 150 grit and they don’t even appear to have a plateauing stone)

I obviously could not continue this build with 20 people (including two machinists) telling me this was badly wrong. I took it to another engine remanufacturing company who were quite shocked at MJA’s workmanship. They agreed to take on the block and sleeved the damaged cylinder and plateau-honed all the cylinders to a much better finish.

MJA’s work was just shockingly bad and ignorant. To make matters worse, their business card had the FER mark on it (Federation of Engine Re-Manufacturers) but when I contacted FER to complain, they said MJA were no longer a member. I queried the reason for this with MJA Engineering but they did not answer this question, so I can only assume they were expelled.

In short, don’t use MJA engineering in Broomsgrove, even if they were on TV. It doesn’t make them experts (clearly).

Here she is, looking sad, left behind with a pile of parts…

After 7 years of sitting, it is finally off to the body shop…

Have taken delivery of:

Will update this post with some photos…