I’m not an expert, definitely don’t use this as a guide 🙂

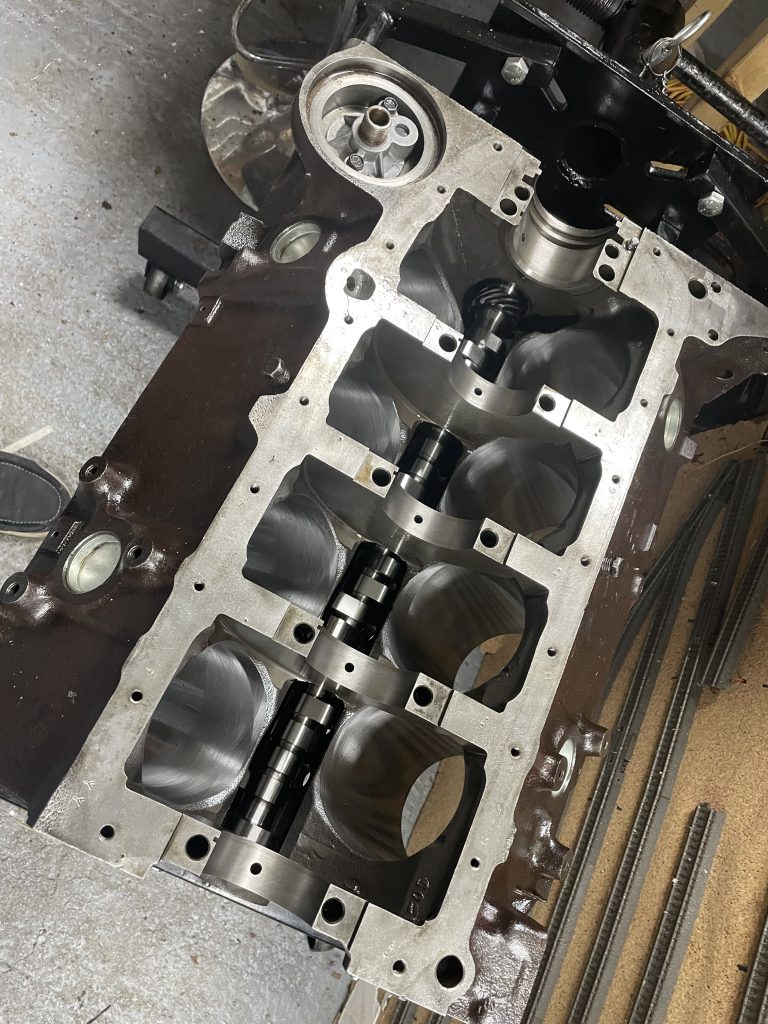

Block with cam fitted.

Crank fitted.

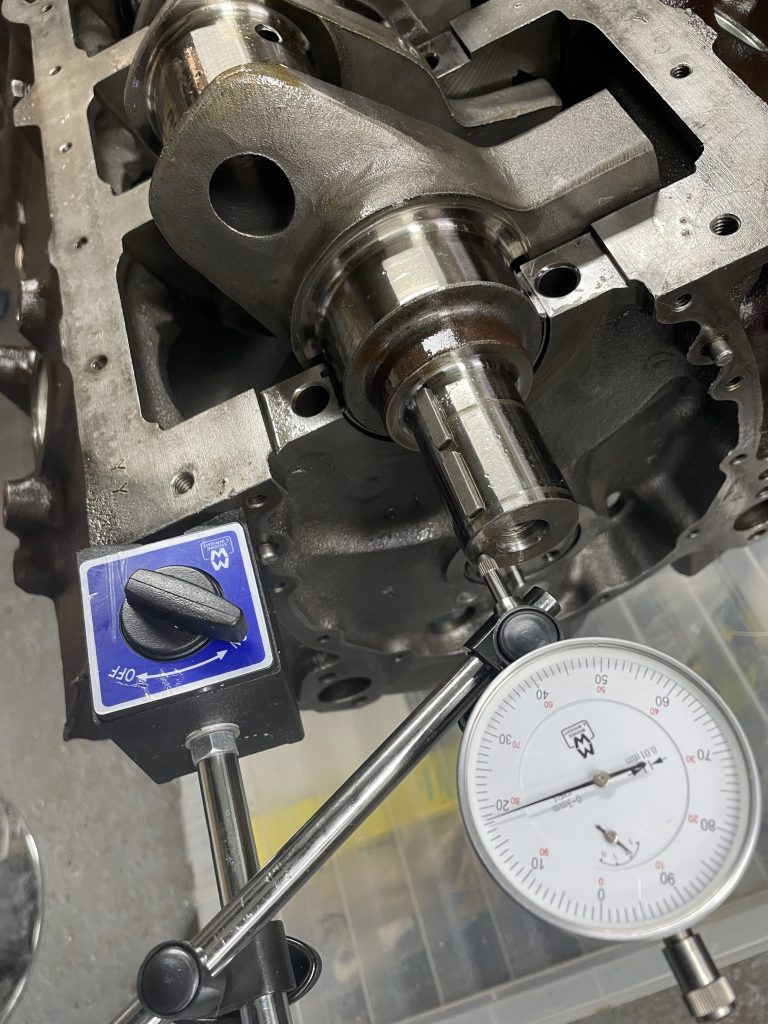

Measuring bearing clearance using Plastigage.

Measuring end-float.

Everything I measured up until this point was within spec. The end-float did drop from 0.0055″ to 0.0028″ when I tightened the thrust bearing but I did shove the crank backwards and forwards before tightening and was told this is normal.

Test spin